Embarking on automotive projects, especially those involving heavy lifting like engine removal or installation, demands not only skill and precision but also the right tools for the job. At the heart of such tasks is the engine crane, an indispensable tool that makes the daunting task of hoisting engines in and out of vehicles safer and more manageable.

Whether you're a seasoned mechanic or a passionate hobbyist, mastering the use of an engine crane will elevate your automotive projects to new heights of success and safety. Let's dive into the world of engine cranes, starting with a solid foundation of what they are, followed by essential pre-operational checklists, operational guidance, and efficiency-enhancing practices.

Understanding Engine Cranes

Engine cranes, also known as engine hoists, are indispensable tools in the realm of automotive maintenance, repair, and engine rebuilding. Their primary function is to lift, hold, and maneuver heavy loads, particularly engines, out of or into a vehicle. This section delves into the basics of engine cranes, highlighting their importance, functionality, and the various types available, providing a foundation for both novices and seasoned users to better appreciate the capabilities and applications of these vital tools.

The Role of Engine Cranes in Automotive Maintenance

Engine cranes are pivotal in performing significant repairs, modifications, or replacements that require accessing the engine compartment. They offer a safe and efficient means to handle the heavy and awkward loads of vehicle engines, ensuring that these complex tasks are completed without injury or damage to the vehicle or components.

Types of Engine Cranes

- Hydraulic Engine Cranes: The most common type, known for their reliability and ease of use. They utilize a hydraulic pump to lift heavy loads effortlessly.

- Electric Engine Cranes: These cranes use electric motors to lift the engine, offering convenience and efficiency, especially in professional settings where power is readily available.

- Manual Engine Cranes: Less common, these require manual effort to operate, making them suitable for smaller engines or occasional use.

Selecting the Right Engine Crane

Choosing the appropriate engine crane involves considering several factors, including:

- Lifting Capacity: Ensuring the crane can handle the weight of your engine is paramount. Cranes typically range from 1-ton (2,000 pounds) to 3 tons (6,000 pounds) in lifting capacity.

- Reach and Height: The crane must be able to reach into the engine compartment and lift to the required height, accommodating different vehicle sizes and engine positions.

- Portability and Storage: Depending on your workspace, you may need a crane that is easy to move and store. Foldable designs offer space-saving solutions without compromising on functionality.

The Importance of Engine Cranes

Engine cranes are not just about lifting; they are about doing so safely and efficiently. The ability to precisely control the lift and position of heavy loads reduces the risk of injury and damage to the vehicle or engine. Furthermore, the right engine crane can significantly enhance productivity in a workshop by streamlining tasks that would otherwise be extremely labor-intensive and time-consuming.

In summary, understanding the fundamental aspects of engine cranes is the first step towards leveraging their full potential in automotive maintenance and repair projects. With the right knowledge and tools, tackling even the most challenging engine tasks becomes manageable and safe.

Pre-Operational Checklist

Before embarking on any task involving an engine crane, it's crucial to perform a pre-operational checklist. This process ensures the safety and efficiency of your project, minimizing the risk of accidents and equipment damage. Here's a detailed checklist to guide you through the necessary steps and inspections before using an engine crane.

1. Inspect the Engine Crane

- Visual Inspection: Check for any visible defects such as cracks, leaks, or damage to the crane structure, especially in the hydraulic system and lifting arm.

- Hydraulic System: Ensure the hydraulic fluid is at the correct level and there are no leaks.

- Wheels and Casters: Verify that they are in good condition, secure, and move smoothly for easy positioning of the crane.

2. Check the Lifting Gear

- Chains and Hooks: Inspect for wear, deformation, or damage. Ensure hooks are equipped with safety latches and chains are of adequate strength for the load.

- Slings and Straps: If used, check for cuts, fraying, or other damage that could compromise their integrity.

3. Assess the Load

- Weight Verification: Confirm the weight of the engine or load to ensure it is within the crane's lifting capacity.

- Lifting Points: Identify secure and balanced lifting points on the load to prevent slippage or tilting during lifting.

4. Prepare the Work Area

- Clear Space: Ensure the area is free of obstacles that could impede the crane's movement or pose a tripping hazard.

- Stable Ground: Verify that the crane is on stable and level ground to prevent tipping during operation.

- Safety Zone: Establish a safety zone around the lifting area to keep bystanders at a safe distance.

5. Plan the Lift

- Lift Path: Plan the path of the lift, considering overhead obstacles, turning points, and the final placement of the load.

- Communication: If working with a team, establish clear signals or communication methods to coordinate the lift safely.

6. Personal Protective Equipment (PPE)

- Ensure all operators and bystanders are equipped with appropriate PPE, including safety glasses, gloves, and steel-toed boots.

Completing this pre-operational checklist not only safeguards the operator and those around but also extends the life of the engine crane by preventing misuse and spotting potential issues before they lead to failure. Taking these steps before each use is a best practice that reinforces a culture of safety and responsibility in any automotive workshop or garage.

Key Safety Protocols for Engine Crane Operation

Ensuring the safety of operators and bystanders is paramount when working with engine cranes. These heavy-duty tools, while indispensable, can pose significant risks if not used correctly. Adhering to key safety protocols can mitigate these risks, ensuring a safe and productive work environment. This section outlines essential safety measures and best practices for operating engine cranes.

Personal Protective Equipment (PPE)

- Safety Footwear: Steel-toed boots can protect your feet from heavy objects that might fall during the operation.

- Gloves: Wear gloves to protect your hands from sharp edges and the possibility of hydraulic fluid contact.

- Eye Protection: Safety glasses or face shields are crucial to safeguard your eyes from flying debris or spills.

Load Balancing and Securement

- Check Load Capacity: Never exceed the crane's maximum load capacity. Always confirm the weight of the engine or load before lifting.

- Secure the Load Properly: Use appropriate lifting attachments and ensure they are securely fastened to the load. Check all hooks, chains, and straps for wear and tear.

- Evenly Balance the Load: Adjust the position of the load to ensure it is balanced on the crane's hook. An unbalanced load can sway or slip, causing accidents.

Operational Best Practices

- Stay Clear of the Load: Never stand under or near a suspended load. Always keep a safe distance in case of unexpected movements.

- Smooth Operation: Operate the crane controls smoothly and slowly to avoid jerking the load. Sudden movements can destabilize the crane and load.

- Communication: If working with others, establish clear communication signals to coordinate movements, especially when visibility is obstructed.

Emergency Preparedness

- Know Emergency Procedures: Familiarize yourself with emergency stop controls and procedures in case of a failure or accident.

- First Aid: Ensure a first-aid kit is readily available and that personnel are trained in basic first aid and know how to respond in case of injury.

Regular Inspection and Maintenance

- While this guide focuses on operational safety, remember that regular inspection and maintenance of the engine crane are critical to ensure it remains in safe working condition.

By adhering to these key safety protocols, operators can significantly reduce the risks associated with engine crane operation. Safety should always be the top priority, as it ensures not only the well-being of the operator but also the efficiency and success of the automotive projects at hand.

Operating an Engine Crane: Step-by-Step Guide

Operating an engine crane requires a blend of precision, care, and adherence to safety protocols to ensure successful lifting and handling of vehicle engines. This guide provides a comprehensive step-by-step approach to operating an engine crane, ensuring efficiency and safety at every turn.

1. Preparation

- Read the Manual: Before using the engine crane, familiarize yourself with its components, capabilities, and specific safety warnings or recommendations from the manufacturer.

- Inspect the Crane: Check for any visible damage, leaks in hydraulic systems, or defective parts that could affect the crane's operation. Ensure all components are secure and in good working order.

- Prepare the Work Area: Clear the area of any obstacles. Ensure the floor is level and capable of supporting the weight of the crane and the engine. Position the crane on a stable, non-slippery surface.

2. Setting Up the Crane

- Extend the Legs: Extend the crane’s legs according to the manufacturer's instructions to ensure stability during lifting.

- Adjust the Boom: Set the boom to the appropriate length and angle for the lift, considering the engine's weight and the required reach.

3. Attaching the Load

- Secure Lifting Points: Identify and attach the crane’s hook to the engine’s designated lifting points. These are usually marked or indicated in the vehicle’s service manual. Use appropriate lifting straps or chains that are in good condition and rated for the load's weight.

- Check Balance: Before lifting, ensure the engine is balanced and secured to prevent swinging or tipping.

4. Lifting the Engine

- Pump the Handle: If using a hydraulic crane, pump the handle to start lifting the engine slowly. Keep a steady pace to maintain control of the load.

- Monitor Clearance: As the engine lifts, carefully watch for any obstacles in the path or points where the engine might catch on the vehicle.

- Pause and Adjust: If necessary, pause lifting to adjust the angle or position to ensure a smooth lift. Never rush this process.

5. Moving the Engine

- Move Slowly: Once the engine is clear of the vehicle, slowly move the crane to the desired location. Avoid any sudden movements or stops that could destabilize the load.

- Lowering the Load: When in position, slowly lower the engine by carefully releasing the hydraulic pressure (or lowering mechanism on manual or electric cranes) until the engine is securely on the ground or a stand.

6. Post-Operation

- Detach the Engine: Once the engine is securely positioned, detach the lifting straps or chains from the engine.

- Return the Crane to Storage Configuration: Retract the boom and legs, prepare the crane for storage, and conduct a post-use inspection to ensure it's ready for next time.

By following these steps and maintaining a focus on safety, you can effectively use an engine crane to lift and transport engines or other heavy components, ensuring a smooth and safe process from start to finish.

Enhancing Efficiency in Engine Crane Operations

Efficiency in using an engine crane not only speeds up automotive projects but also reduces the risk of injury and damage to components. Here are strategies to enhance the efficiency of your engine crane operations:

Optimize Workspace Layout

- Organized Workspace: Arrange your workspace to allow easy maneuverability of the engine crane. Ensure a clear path for moving engines to and from the work area.

- Tool Accessibility: Keep tools and equipment needed during the lift within reach but out of the way to avoid clutter and potential hazards.

Pre-Plan Your Lift

- Assess the Task: Before lifting, assess the task ahead. Understand the weight distribution of the engine and any components that may need removal to lighten the load or balance it better.

- Plan the Route: Consider the best path for moving the engine, identifying any obstacles and planning how to navigate around them.

Regular Maintenance Checks

- While this guide focuses more on operational efficiency, it's worth noting that regular maintenance checks of the crane can prevent downtime. Ensure hydraulic fluids are at the right level, and all moving parts are lubricated.

Use the Right Accessories

- Appropriate Lifting Gear: Use slings, chains, or lifting straps that are suited for the engine’s weight and have secure attachment points. This ensures a safe and efficient lift.

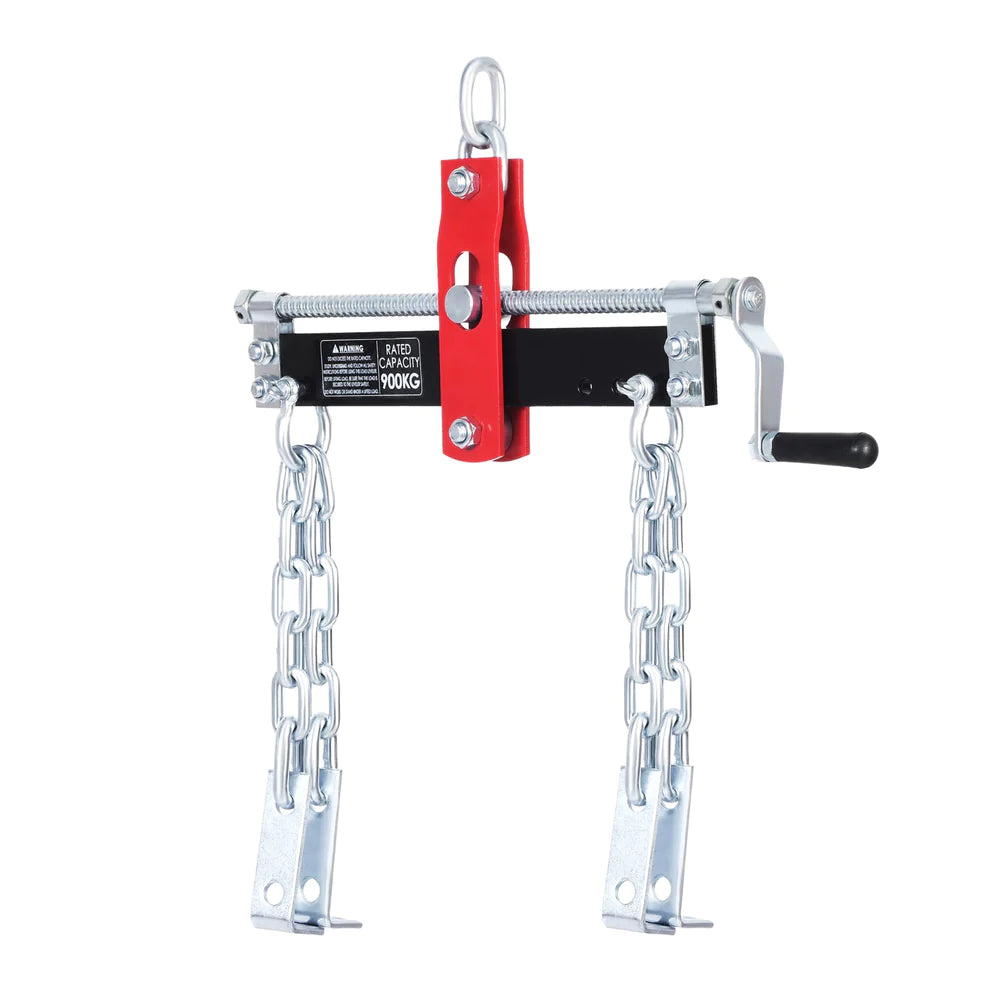

- Engine Leveler: An engine leveler can greatly enhance control over the load, allowing you to adjust the angle of the engine easily as it's being lifted or lowered. This tool is invaluable for positioning the engine precisely during removal or installation.

Train and Educate Operators

- Proper Training: Ensure anyone operating the engine crane or assisting in the operations is properly trained. Knowledge of the crane’s functions, load limits, and safety protocols is essential.

- Continuous Learning: Encourage a culture of continuous improvement and learning. Sharing tips and experiences among team members can lead to more efficient practices.

Implement Safety Measures as Efficiency Practices

- Safety Equals Efficiency: Every safety protocol followed is a step towards more efficient operations. Safe practices prevent accidents, which in turn avoids delays and potential damage to parts or equipment.

Review and Reflect Post-Operation

- Post-Operation Analysis: After completing a project, take time to review the process. Identify any steps that caused delays or issues and discuss potential improvements for future operations.

Leverage Technology

- Use Technology Tools: Modern tools and apps can assist in planning lifts, managing maintenance schedules, and even training operators through simulations. Explore technological solutions that can streamline operations.

By focusing on pre-planning, workspace optimization, proper use of accessories, continuous learning, and integrating safety into every step, you can significantly enhance the efficiency and productivity of engine crane operations. These practices not only save time but also ensure a safer environment for everyone involved.

As we wrap up this exploration of engine crane operations, covering everything from setup and operation to safety and efficiency improvements, we've aimed to arm you with the knowledge needed to elevate your automotive projects. Operating an engine crane with precision and care not only enhances project outcomes but ensures the safety of all involved. As you apply the insights from this guide, each task you undertake can become a step towards more effective and safer engine handling.

For those eager to dive deeper and explore further, we encourage you to explore our listing and delve into our in-depth guide. Whether you're in the market for a new engine crane or looking for advanced operational strategies, our resources are designed to support your journey. Embrace the opportunity to enhance your skills and knowledge, and let each project be a testament to your commitment to excellence in automotive maintenance and repair.